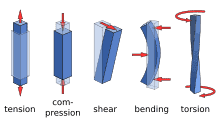

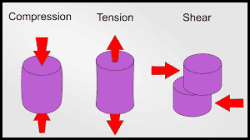

When designing and building things, one must consider the stresses that they will face. The stress-strain relationship in compression and tension is the same. The yield point is the point at which strain exceeds stress and the material undergoes permanent deformation. This point may vary depending on the material. The stress-strain relationship varies from material to material, so it is important to understand the nature of stress before constructing or using something.

A material’s stress limits refer to the amount of force that a material can withstand without breaking. These limits are called fatigue strengths. When these limit values are exceeded, a material’s fatigue strength is exceeded and it does not return to its original shape. In contrast, plastic deformation occurs when a material is strained beyond its yield strength and does not return to its original shape. Plastic deformation is similar to a child’s silly putty, and its strength is determined by the amount of deformation the material undergoes. The stress term refers to the force applied to a material over a specific area. Tensile stress is a force that pulls a material apart.

Engineers develop a part’s design based on the mechanical properties of the material. They also consider the stresses a material will face. In most cases, they won’t design a part that requires stress above the material’s yield strength. This is because failure occurs in areas of concentrated stress. Stress concentrations also compromise structural integrity. For this reason, engineers are aware of the importance of considering the effects of fatigue cracks. Surface Treatments are commonly applied to materials to increase their strength for this reason. Find out more at a site like Poeton Surface Treatments

When designing products with localised stresses, engineers should carefully consider how the stresses on a part will affect the structure. These stresses are known as stress concentrations and they often occur when an object has irregular shapes or is subjected to a sudden change in cross-sectional area. They are best avoided by designing components with a smooth transition between critical areas of the design. If there is a change in geometry, this will cause the material to break down.

In science, students can learn about the concept of stress and strain. They explore what factors affect stress and why engineers should know about it. They can then apply their newly learned knowledge by explaining the role of stress in engineering and providing examples. When they are finished, students can then decide whether or not stress considerations relate best to yield strength or ultimate tensile strength.